Overview

The Defect Sorting Inspection (DSI), also known as 100% Inspection, is a comprehensive quality control process designed to identify and remove defective products before shipment. Unlike random sampling inspections, DSI involves inspecting every single unit to ensure that only defect-free products are delivered to customers.

During this process, inspectors carefully examine each item and classify defects as minor, major, or critical, removing all non-conforming products from the batch. DSI is especially valuable when earlier inspections reveal a high defect rate or when buyers require strict quality assurance to prevent defective goods from reaching the market.

.

Who Conduct the Defective Product Sorting Service

At QCC Inspection, our Defect Sorting Inspection (DSI) service is conducted by a team of experienced quality control inspectors who specialize in product defect detection and classification. Each inspector is professionally trained to follow international inspection standards (AQL, ISO 2859) and your specific product requirements.

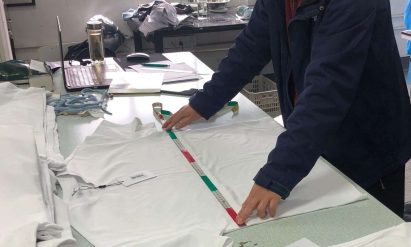

Our inspectors operate on-site at your factory or warehouse, using standardized procedures and detailed defect checklists to ensure accuracy and consistency. They carefully identify, categorize, and remove non-conforming products, ensuring that only defect-free items are approved for shipment.

Report & Results

The DSI report provides detailed defect photos, a clear summary of sorting results, precise defect classifications, and actionable recommendations for improvement. Delivered within 24 hours, it equips you with the insights needed to make fast, informed shipment decisions and maintain consistent product quality control.

Frequently Asked Questions (FAQ)

Get Started with Defect Sorting Inspection

Need to sort out defective items before shipment? Click below to request a sample report or submit an inquiry form, and our team will assist you promptly.