Overview

The Initial Production Check (IPC), also known as Pre-Production Inspection (PPI), is an essential quality control procedure performed before mass production begins. It verifies that all raw materials, components, and production setups comply with the quality standards specified in your purchase order.

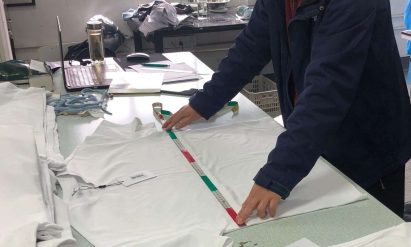

During IPC, inspectors focus on product specifications, raw material quality, and manufacturing processes, while also evaluating the factory’s production capacity, equipment, and readiness. By identifying potential issues at an early stage, IPC helps ensure a smooth production process, reduce quality risks, and prevent costly defects later in the supply chain.