Overview

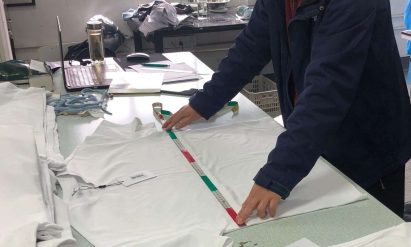

Production Monitoring (PM) is a continuous on-site quality control service that tracks every stage of the manufacturing process to ensure production stays on schedule and meets quality standards. This real-time inspection helps detect potential delays, inefficiencies, or material issues early, allowing for immediate corrective actions to keep operations running smoothly.

The service covers workforce efficiency, machinery performance, material usage, and workflow consistency, providing full visibility into production progress. Inspectors deliver daily updates and actionable insights, enabling manufacturers to identify risks before they escalate.

By implementing Production Monitoring, companies can minimize production delays, optimize workflow efficiency, and ensure that final goods meet quality requirements and delivery timelines, strengthening both supply chain performance and customer satisfaction.

Report & Results

The daily Production Monitoring (PM) report provides a comprehensive overview of your production status, featuring photos, progress updates, defect analysis, and recommended corrective actions. Delivered every day, it gives you real-time insights into production quality and schedule performance, helping you maintain full control over your manufacturing process.

Frequently Asked Questions (FAQ)

What is included in the daily PM report?

The report features photos, production progress updates, defect analysis, and recommendations for corrective actions.

How is Production Monitoring different from regular inspections?

Production Monitoring provides continuous, real-time oversight throughout the entire production process, whereas regular inspections are conducted at specific stages.

Get Started with Production Monitoring

Want continuous oversight of your production process to ensure consistent quality? Click below to request a sample report or submit an inquiry form, and our team will assist you promptly.